Commitment to Facility Improvement

Higher Quality.

Every day, at Katsushiro MATEX, we strive for facility improvement to keep up with new technologies. We believe that upgrading our facilities allows us to deliver more precise products at a faster pace. Additionally, as part of our environmental responsibility, we are actively introducing cleaner facilities.

Fiber Laser Cutting Machine

We have achieved efficiency in the cutting process and product handling process by combining raw material stocking and automatic picking machines. Additionally, automating the handling process has contributed to improved safety.

Automation of Welding Processes

We have improved quality and productivity by utilizing welding robots. Moreover, the collection of fumes generated during welding with a large dust collector has led to an improved working environment.

Material Handling Robots

By combining material handling robots with drilling centers and cutting equipment, we have automated loading and unloading processes, ensuring safe and high-quality production.

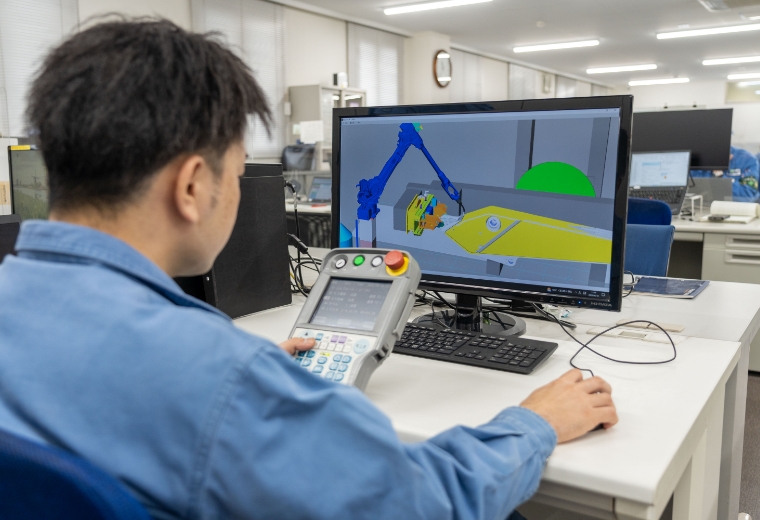

Offline Teaching

We conduct teaching of welding robots and CNC machines in a virtual space on computer screens. This allows us to perform safe and efficient teaching without stopping production lines while also enabling the replication of Japanese factory quality in overseas factories.

Push-Pull Dust Collector

We achieve high-speed cutting of thick plates using high-output plasma cutting machines. Additionally, by combining push-pull dust collectors, we collect fumes generated during processing, contributing to environmental improvement within the factory and employee health promotion.

On-Site Tablets

We are committed to environmentally friendly manufacturing. By introducing tablet devices, we can check drawings, procedures, and enter production data in the manufacturing field. This allows us to achieve timely production management while reducing paper usage.